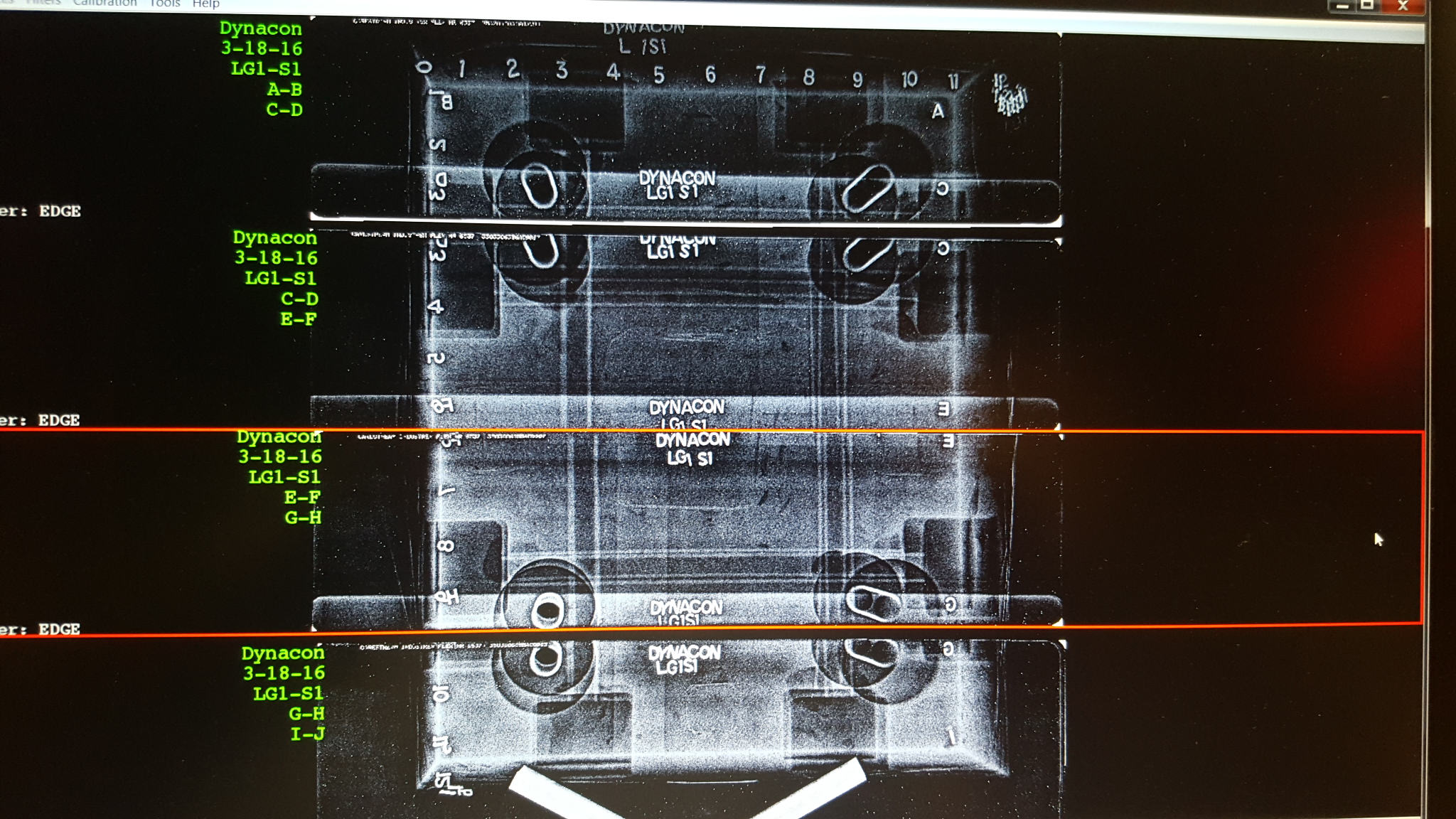

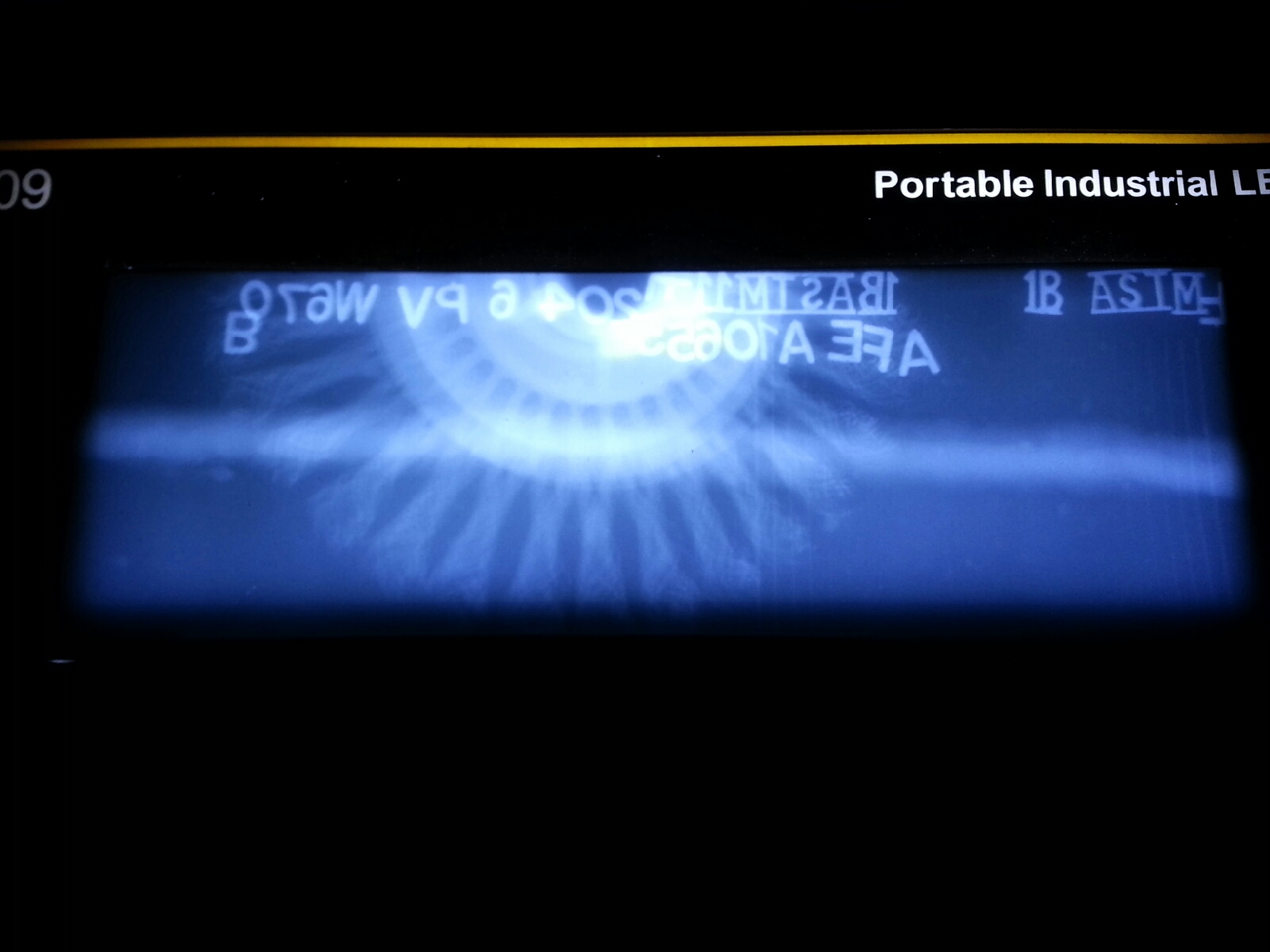

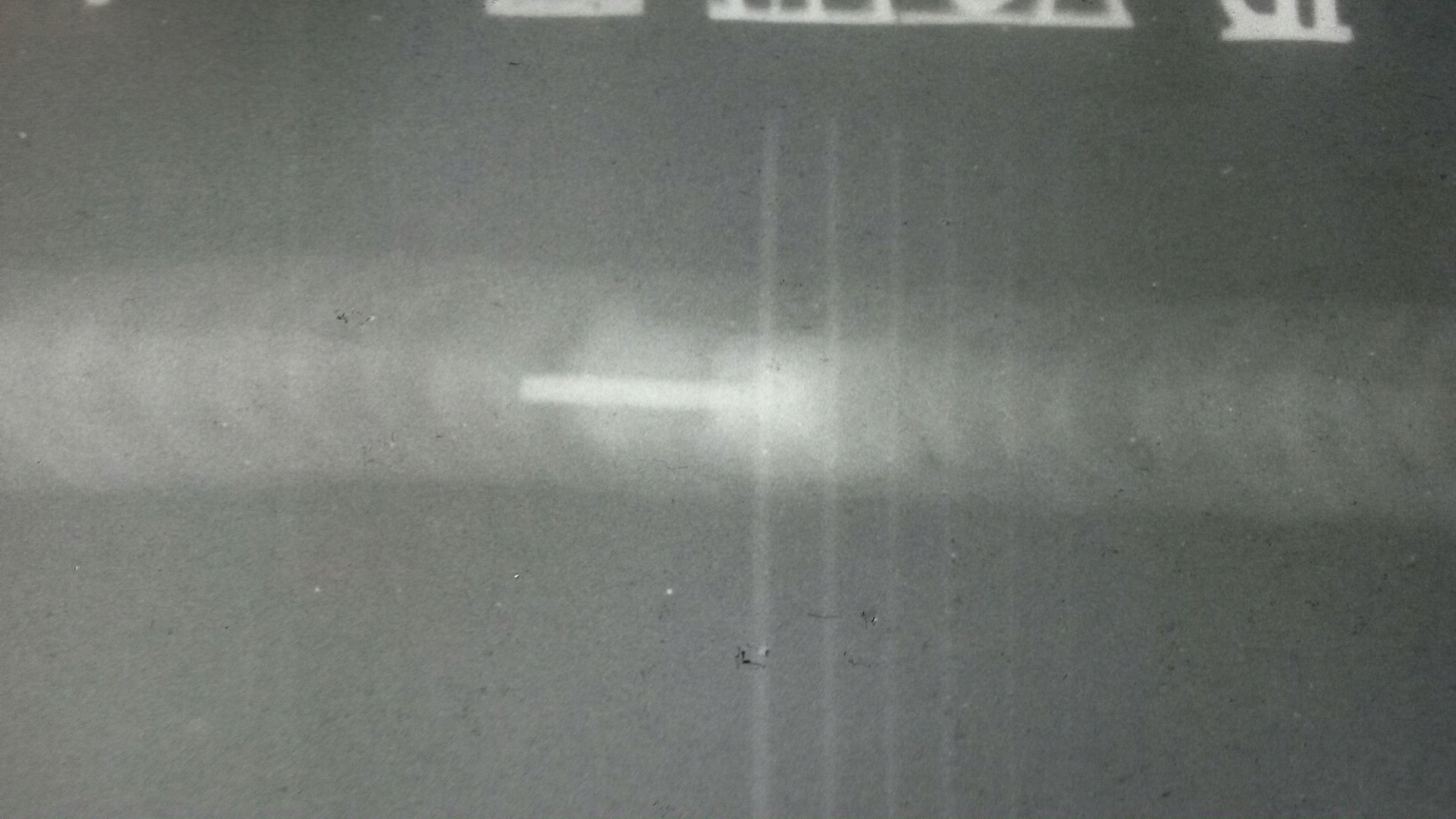

Radiographic Testing (RT)

NDE Solutions LLC specializes in traditional gamma radiography using film for the inspection of welds and other related materials. Our crews are experienced in the x-ray inspection of pipelines, gathering systems, and pipe and vessel fabrication shops.

All of our technicians are capable of producing top quality film due to the thorough training programs and detailed procedures administered by our multiple ASNT Level III personnel. We strive to provide audit quality images on every project and actively seek customers that value a high level of workmanship and service.

We take pride in the productivity of our x-ray crews. When quoting pipeline projects, we guarantee to meet our specified mainline production rate.

Liquid Penetrant Testing (PT)

NDE Solutions LLC provides visible, solvent removable penetrant testing in field applications. These tests can be performed to detect surface flaws on welded materials, base metals, fittings, or other large non-porous test areas. Due to the bleed out of the penetrant into the developer, very small indications that are difficult or impossible to see with the eye can be effectively located.

Penetrant testing is an efficient way to test multiple or very large parts for surface defects. We offer this service in conjunction with our other services or as a stand-alone service when needed.

Magnetic Particle Testing (MT)

NDE Solutions LLC uses contrasting particles in either a dry or wet form, with portable yokes, to perform magnetic particle inspection in field applications. These tests can be performed to detect surface and some near-surface flaws on welded materials, base metals or fittings that have the ability to be magnetized.

Magnetic Particle inspection requires minimal equipment and provides nearly instant feedback; therefore, it is a very efficient method in both time and cost. We offer this service in conjunction with our other services or as a stand-alone service when needed.

Ultrasonic Thickness Testing (UTT)

NDE Solutions LLC provides wall thickness verification and measurement through the use of portable ultrasonic thickness gauges. We can provide readings from single point measurement gauges or gauges that produce A-scan, B-scan and thru paint measurement. Whether you are looking to verify wall thickness before welding hot taps, split-tees, sleeves or you just have a material of unknown thickness we have the tools and technicians to assist you.